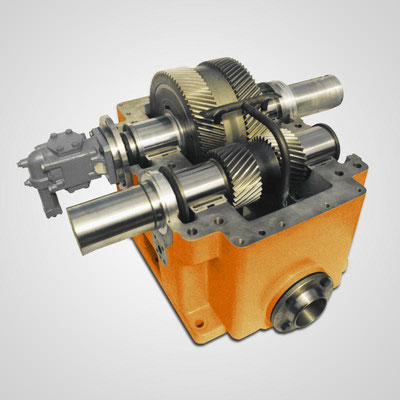

Transmissions must reliably ensure maximum performance in complex production lines and machines – sometimes around the clock, often under extreme conditions. Such mechanical stress leaves permanent traces that may lead to defects beyond normal wear up to fatal damage and even total failure of a system or machine. These risks can be minimized through early identification of incipient gear defects as part of regular transmission maintenance.